Abutment Matching POC

3D dental mesh processing system for abutment identification and matching

🔒 Closed Source

2025-05-21

View on GitHubSTL ProcessingSegmentationMedical AI

The Abutment Matching Pipeline is a Proof-of-Concept 3D computational geometry system designed to bridge the gap between digital dental scans and prosthetic component selection. This processes segmented jaw scans to identify implants, analyze their geometry and orientation, and perform precise spatial alignment to enable automated abutment selection for dental prosthetics.

This project is developed using private data and is designed to be extensible for industry use cases, research initiatives, and potential product development. If you’re interested in exploring collaborations or adapting this work for real-world applications, feel free to reach out to discuss possibilities.

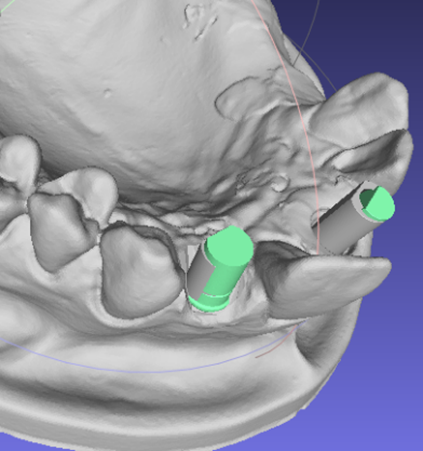

Segmented jaw scan with color-coded implants, teeth, and tissue structures.

System Workflow

Pipeline Components

The system implements the following key components:- Isolating the scanbody regions from the full jaw model

- Identifying and clustering the implants separately from teeth

- Matching each external implant with a compatible one from the STL library

- Replacing the new implant with orientation-accurate alignment

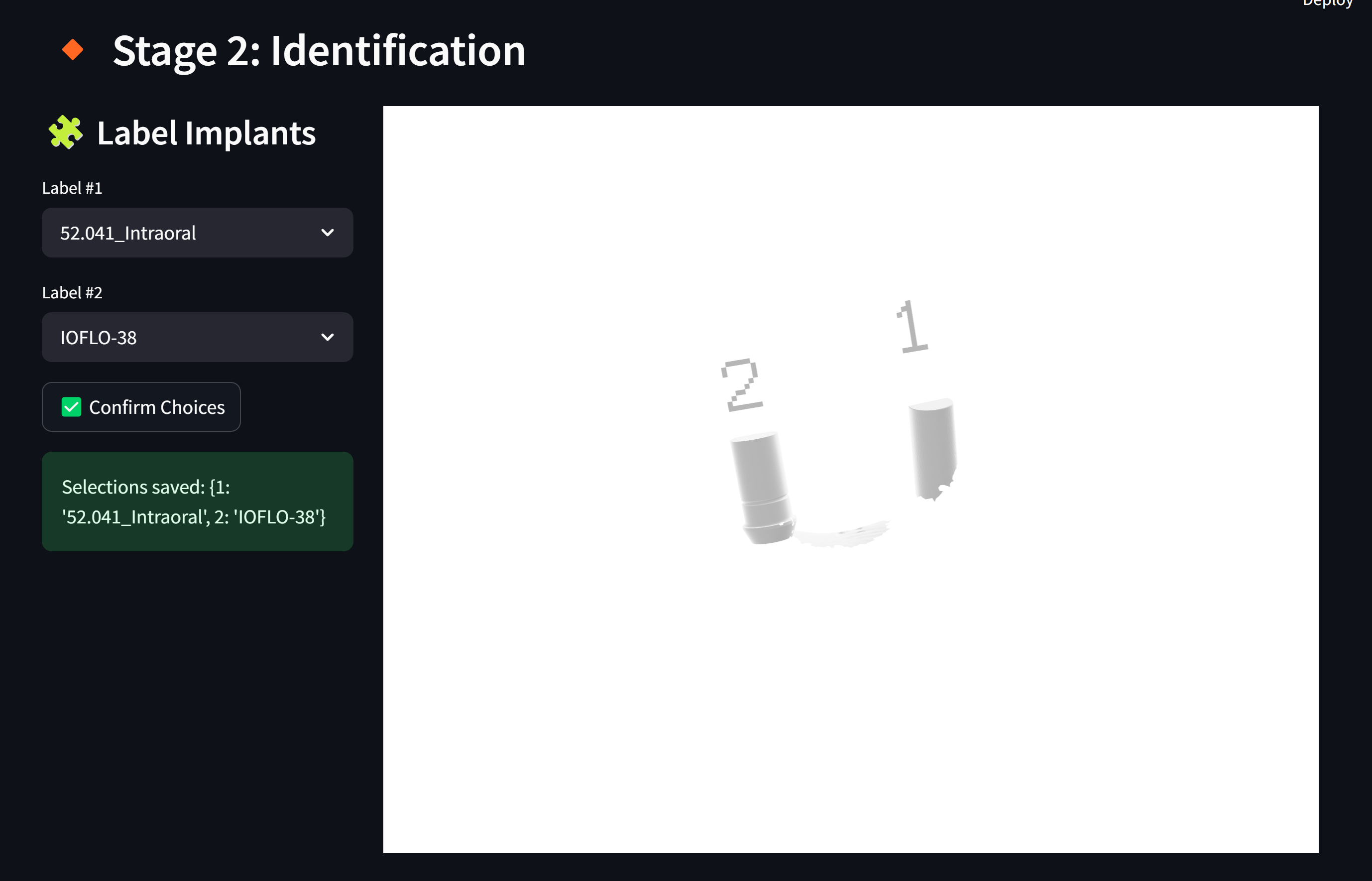

Pipeline Visualization

The system provides a range of visualization capabilities:

- Interactive 3D Viewer: Built with Open3D's visualization module for real-time mesh inspection

- Color-Coded Meshes: Different colors for implants, teeth, tissue, and labels

- Numbered Labels: 3D text meshes positioned above implants for clinical identification

- Multi-View Rendering: Support for different camera angles and perspectives

Interactive 3D visualization with color-coded meshes and oriented bounding boxes.

Use Cases & Applications

- Digital Dentistry: Automated prosthetic component selection from dental scans

- Treatment Planning: Precise implant positioning and orientation analysis

- Quality Assurance: Validation of implant placement accuracy

- CAD/CAM Integration: Bridge between scanning and manufacturing workflows